Recommended Liquid Detergent Mixing Machines For Cosmetic Fields

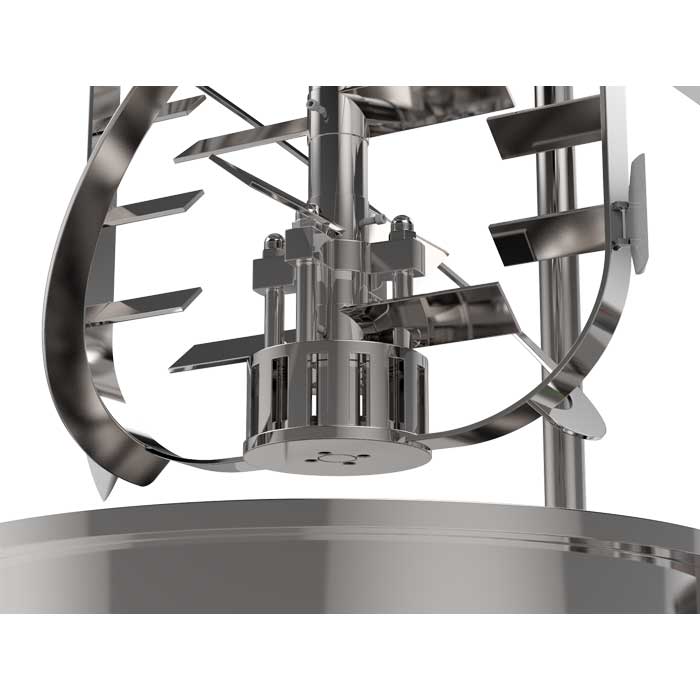

A liquid vacuum cosmetics emulsifier mixer is a device designed to mix ingredients used in the production of liquid detergent. It typically consists of a tank, a motor, a mixing blade, and various sensors and controls. The tank is usually made of stainless steel and is used to hold the raw materials used to make the detergent. The motor powers the mixing blade, which is responsible for blending the ingredients together. The sensors and controls on the machine help to regulate the mixing process, ensuring that the ingredients are thoroughly mixed and that the mixture remains at the desired temperature and consistency.

Some liquid detergent mixing machines also include additional features, such as heating elements, cooling systems, and automated dispensing systems for ingredients. Overall, a liquid detergent mixing machine can greatly simplify the process of making liquid detergent, allowing manufacturers to produce high-quality products efficiently and consistently.

Brief Introduction About Cosmetic Mixing Machine

Yuxiang’s cosmetic mixing machine is a specialized device designed to blend and homogenize cosmetic ingredients to create high-quality cosmetic products. It is an essential tool for manufacturers in the cosmetic industry, as it ensures consistent and precise mixing of various ingredients to create a uniform and stable final product. The cosmetic mixing machines come in a variety of sizes and designs, ranging from small tabletop models to large industrial-scale machines. They typically feature a mixing vessel or tank, a motor, a mixing blade, and various controls and sensors.

The mixing vessel is typically made of stainless steel and is designed to withstand the corrosive effects of various cosmetic ingredients. The motor powers the mixing blade, which is responsible for thoroughly blending the ingredients together. Cosmetic mixing machines may also include additional features, such as temperature control systems, vacuum systems for de-aerating the mixture, and automated dosing systems for precise ingredient measurement. Besides, Cosmetic mixing machines are used in a wide range of cosmetic product manufacturing processes. Some of the most common applications of cosmetic mixing machines include:

-

Creams and lotions: Cosmetic mixing machines are used to mix ingredients such as oils, water, and emulsifiers to create stable emulsions that are used in the production of creams and lotions.

-

Shampoos and conditioners: Mixing machines are used to blend ingredients such as surfactants, conditioning agents, and fragrances to create high-quality shampoos and conditioners.

-

Soaps: Cosmetic mixing machines are used to blend ingredients such as oils, lye, and fragrance oils to create high-quality soaps.

-

Makeup products: Mixing machines are used to blend ingredients such as pigments, emollients, and waxes to create high-quality makeup products such as lipsticks, foundations, and eyeshadows.

-

Sunscreens: Mixing machines are used to blend ingredients such as UV filters, emulsifiers, and antioxidants to create high-quality sunscreens that provide broad-spectrum sun protection.

How To Choose the Right Cosmetic Mixing Machine ?

Choosing the right cosmetic mixing machine is essential to ensuring the success of your cosmetic manufacturing business. Here are some tips to help you choose the right machine for your business needs:

Consider the volume of cosmetics that you want to produce and choose a mixing machine that can handle your production needs. This will help you avoid underutilization or overloading of your machine and Identify the types of cosmetics you will produce, Different types of cosmetic mixing machines are designed to handle different types of ingredients, such as oils, waxes, surfactants, and thickeners. Identify the ingredients you will be using and choose a machine that is compatible with those ingredients.

Choose the right capacity: The capacity of a mixing machine refers to the amount of product that it can process in a single batch. Choose a machine with a capacity that matches your production volume and the size of your mixing vessels. Mixing speed and power are important factors to consider when choosing a mixing machine. Choose a machine with the appropriate speed and power to ensure that all ingredients are mixed thoroughly and homogenously. Automation and control features can help you optimize your mixing process and increase efficiency. Look for machines with features such as programmable settings, real-time monitoring, and automated dispensing systems.

Evaluate the maintenance and cleaning requirements: The maintenance and cleaning requirements of a mixing machine are important considerations when choosing a machine. Choose a machine that is easy to clean and maintain to ensure consistent quality and longevity of the machine. By following these tips, you can choose the right cosmetic mixing machine that meets your production needs, matches your ingredients and capacities, and increases efficiency and quality of your cosmetic production. Here are some detailed cosmetic mixing machine for reference.

Lipstick Mixing Machines Brief Details

Our lipstick mixing machines are a vital tool in the cosmetic industry, designed to mix and blend the various ingredients required for the creation of a flawless lipstick product. These machines offer a fast, efficient, and reliable method for producing high-quality lipstick in large quantities, making them an indispensable component of the cosmetics manufacturing process. Next, we will explore the workings of lipstick mixing machines, their benefits, and their importance in the cosmetics industry.

Lipstick mixing machine is a specialized piece of equipment used in the production of lipsticks. The machine works by mixing and blending the various ingredients required to make the lipstick, including waxes, oils, pigments, and other additives. The machine is designed to ensure that all the ingredients are mixed thoroughly and evenly, resulting in a consistent and high-quality final product. Lipstick mixing machines come in a variety of designs, but the basic principles of operation are similar. The machine consists of a mixing chamber where the various ingredients are combined and blended. The chamber is typically equipped with a motor that drives a mixing blade or paddle, which agitates the ingredients and ensures that they are thoroughly mixed.

The ingredients for the lipstick are loaded into the mixing chamber, and the machine is started. The mixing blade or paddle rotates, creating a vortex that draws the ingredients towards the center of the chamber, where they are blended together. The speed and duration of the mixing process can be adjusted to achieve the desired consistency and texture of the final product. Once the ingredients are mixed, the lipstick is typically poured into molds, where it is allowed to cool and solidify. The molds can be designed to produce lipsticks in a variety of shapes and sizes, from traditional cylindrical shapes to more complex designs.

Benefits of Using A Lipstick Mixing Machine

Yuxiang Lipstick mixing machines offer a wide range of benefits for cosmetics manufacturers. Some of the key advantages of using these machines include:

-

Consistency: Lipstick mixing machines are designed to ensure that all the ingredients are mixed thoroughly and evenly, resulting in a consistent final product. This consistency is vital for maintaining the quality of the lipstick and ensuring that customers receive a product that meets their expectations.

-

Speed: Lipstick mixing machines are capable of producing large quantities of lipstick in a relatively short amount of time. This makes them an ideal choice for cosmetics manufacturers who need to produce high volumes of product to meet customer demand.

-

Efficiency: Lipstick mixing machines are highly efficient, requiring minimal manual labor and reducing the risk of human error. This not only saves time and money but also helps to ensure that the final product is of a consistent quality.

-

Versatility: Lipstick mixing machines can be customized to meet the specific needs of cosmetics manufacturers. They can be designed to produce lipsticks in a variety of colors, textures, and finishes, giving manufacturers the flexibility to create a wide range of products to meet customer demand.

-

Cost-effective: Lipstick mixing machines are a cost-effective solution for cosmetics manufacturers. They offer a high level of efficiency and consistency, which helps to reduce waste and minimize the need for expensive manual labor.

Comparison With Shampoo Mixing Machine

Yuxiang’s shampoo mixing machine is a piece of equipment that is designed to mix together various ingredients to create a uniform and consistent shampoo product. The machine typically consists of a mixing tank, which is where the ingredients are blended together, and an agitator, which is a device that mixes the ingredients by creating turbulence in the mixture. The machine may also include pumps to transfer ingredients from storage tanks to the mixing tank, sensors to monitor the temperature and pressure of the mixture, and a filtration system to remove any impurities or particles in the shampoo product. Shampoo mixing machines are used by companies that produce shampoo in large quantities to ensure consistent quality and reduce the time and effort required to mix ingredients by hand. The lipstick mixing machine and a shampoo mixing machine are similar in that they are both used to blend and homogenize ingredients to create high-quality products. However, there are some key differences between the two machines:

-

Design: Lipstick mixing machines are designed to handle a wide variety of cosmetic ingredients, including oils, emulsifiers, and fragrances. Shampoo mixing machines, on the other hand, are designed specifically for the mixing of surfactants, conditioning agents, and other ingredients used in the production of shampoos and conditioners.

-

Mixing process: The mixing process for cosmetic ingredients is typically more complex and requires longer mixing times compared to shampoo ingredients, which can be mixed quickly and efficiently using a shampoo mixing machine.

-

Scale: As cosmetic, Lipstick mixing machines are available in a wide range of sizes, from small tabletop models to large industrial-scale machines. Shampoo mixing machines are typically smaller and are designed for use in smaller-scale operations.

-

Cost: The cost of a lipstick mixing machine is typically higher than a shampoo mixing machine due to the increased complexity of the mixing process and the wider range of ingredients that can be handled.

Lipstick mixing machines are designed to mix ingredients thoroughly and evenly, ensuring that the finished product is consistent every time. This is important for maintaining the quality and integrity of the product, as well as meeting customer expectations. What’s more, Mixing lipstick by hand can be time-consuming and labor-intensive, especially in large-scale production environments. Lipstick mixing machines can mix large batches quickly and efficiently, allowing cosmetic companies to produce more products in less time.

Yuxiang Lipstick mixing machines can be programmed to mix ingredients in specific ratios and quantities, allowing companies to create custom shades and formulations for their customers. This allows cosmetic companies to differentiate themselves from competitors and offer unique products that meet the specific needs and preferences of their target audience. This allows cosmetic companies to differentiate themselves from competitors and offer unique products that meet the specific needs and preferences of their target audience.

-

01

Australian Customer Placed Two Orders for the Mayonnaise Emulsifier

2022-08-01 -

02

What Products Can the Vacuum Emulsifying Machine Produce?

2022-08-01 -

03

Why Does the Vacuum Emulsifier Machine Be Made of Stainless Steel?

2022-08-01 -

04

Do You Know What is 1000l Vacuum Emulsifying Mixer?

2022-08-01 -

05

An Introduction to the Vacuum Emulsifying Mixer

2022-08-01

-

01

Recommended Liquid Detergent Mixing Machines For Cosmetic Fields

2023-03-30 -

02

Understanding Homogenizing Mixers: A Comprehensive Guide

2023-03-02 -

03

The Role of Vacuum Emulsifying Mixer Machines In The Cosmetic Industry

2023-02-17 -

04

What is a Perfume Production Line?

2022-08-01 -

05

How Many Kinds of Cosmetic Making Machinery Are There?

2022-08-01 -

06

How to Choose a Vacuum Homogenizing Emulsifying Mixer?

2022-08-01 -

07

What Are the Versatility of Cosmetic Equipment?

2022-08-01 -

08

What is the Difference Between RHJ-A / B / C / D Vacuum Homogenizer Emulsifier?

2022-08-01